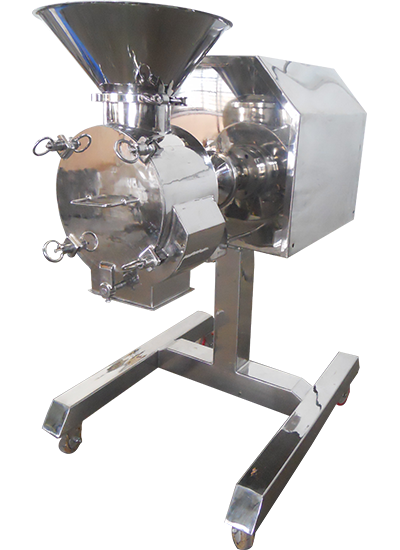

Hammer mills are particularly well suited for the fine milling of powders. The Lab hammer mill has been radically redesigned, substantially increasing efficiency.

The Hammer lab milling head comprises the following process modules.

Rotary paddle feeder and milling chamber with high speed rotor. The product is sized by a sieve in the milling chamber, resulting in a fine powder with optimum particle size distribution and large active sieve surface. It is only hammer mill in the size class in which the head is interchangeable with a conical sieve mill. In a hammer mill, the product is pulverized by impact on the rotor and the shearing forces acting between the particles.

Features

- A dynamically balanced rotor with special alloy steel hammers rotating at very high speeds.

- Hammers and multiple deflectors are made out of SS 304.

- For manual feeding system a tray and throat is provided

- All contact parts in stainless steel 304.

- Retaining screen of various hole sizes to give fineness requires mesh at extra cost.

- All parts can be easily removed and cleaned. All MS non contact parts are cladded in SS 304.